The Science Behind Propeller Sizing Calculator: How It Helps You Find the Right Fit for Your Vessel

Choosing the correct propeller for your vessel is both an art and a science that directly affects your boat’s performance, fuel economy, and handling. The whole process can feel overwhelming, with many variables involved: engine details, hull design, and application. Here is where the propeller sizing calculator is handy. These calculators use precise mathematical algorithms and key data inputs to arrive at a decision, simplifying the purchase process and ensuring perfect compatibility and optimum performance for your boat. In this article, we will explore the science behind propeller sizing calculators, analyze how these tools work, and discuss why they are essential for every boat owner seeking maximum efficiency and performance.

Understanding Propeller Size and Its Importance

Impact of Propeller Size in Vessel Performance

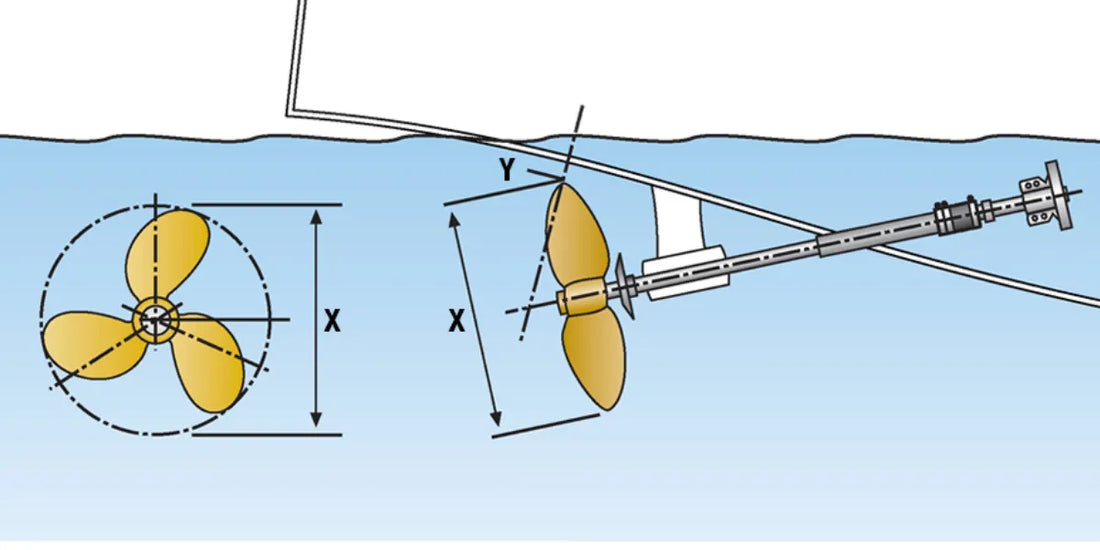

Of utmost importance for vessel performance, efficiency, and handling qualities is the size of a propeller. Since this interaction determines speed and, hence, fuel consumption and engine performance, it affects an engine's ability to push power into the water. Two fundamental measures of a propeller must be accurately fitted to the boat specifications: diameter and pitch. These dimensions respond to hull type, engine power, and use.

Example: High-pitch propellers may give you better speed but are said to drag in slow maneuvers such as docking or towing. Higher speed would be given to the low-pitch propellers at low speeds for heavy loads or water sports. The proper selection helps the engine remain within desired RPM ranges without overloading or underloading, which otherwise would cause premature wear or high fuel consumption. Real situations indicate a 20% loss in efficiency due to improper propeller size, justifying the need for precise calculations. Understanding in detail the relationship between propeller sizing and vessel dynamics enhances performance for the boat owners and a good investment.

Factors Affecting Propeller Size Selection

To optimize the propeller and achieve maximum efficiency while operating the boat, a few major considerations must be evaluated. One primary consideration is the engine's power rating and RPM range. The propeller should be chosen such that its operation will allow the engine to operate at the RPMs for which it has been designed. This will give the engine consistent performance and keep it reliable without putting strain or making it inefficient.

The next aspect affecting the choice of propeller is weight and hull type. A heavier vessel or one with a displacement hull usually requires a larger, slower-turning prop to create thrust, while a lighter vessel or one with a planing hull may opt for a smaller, faster-turning prop to achieve higher speeds.

Furthermore, the condition of water and intended use are important considerations. For example, vessels traveling through shallow waters or areas with heavy debris might have propellers designed for excellent strength and damage resistance. Conversely, ships doing heavy towing work may need propellers that have a larger blade surface area for higher torque.

Advances in propeller material and design technology have also altered the criteria for selecting sizes. Modern propellers are now available in stainless steel or composite materials that rank higher in strength-to-weight ratio and have performance traits. When all these are carefully analyzed and matched with the latest advancements in technology, very precise sizing can be accomplished, considering fuel economy, reduced engine wear, and improved overall vessel operation.

Disbelieving About Propeller Size

Propeller size is one common misconception in the market: Larger props mean better performance. Though largeness in diameter could increase thrust, it also advertises an overstressing of the engine, and hence, more fuel would be consumed. In the long run, too much operational load can cause the drivetrain to deteriorate. On the other hand, small propellers are often charged with inefficiency. The truth is that they may indeed be doing the best work under lighter load conditions, where high RPMs are required.

Another common mix-up is that people assume pitch should stay constant from one application to another. While high-pitch propellers can generate faster speeds, they decrease acceleration and low-end torque, making them inappropriate for vessels commonly engaged in heavy loads or requiring fast manoeuvrability in the area. Contrarily, low-pitch selections may increase pull power but will limit maximum speeds, thus making them inefficient in applications that require fast cruising.

Additionally, some individuals assume that material selection has only a slight influence on sizing. In contrast, in truth, the advent of high-strength composites and stainless steel has made it possible for propellers to sustain high strength while becoming thin in blade profile. This flexibility in design directly enters the sphere of performance considerations, such as cavitation resistance and hydrodynamic efficiency, which cannot be overlooked in any discussions about propeller sizing.

The correct way to size a propeller entails a complex process that demands careful consideration of the engine horsepower, vessel type, and working conditions. Simplistic assumptions often lead to the choice of setups that are less than optimum. To that extent, technical data and instructions should always be consulted whenever discussing propeller selection in marine settings.

What is a Propeller Sizing Calculator?

How Does a Propeller Calculator Work?

To choose propeller specs that suit a particular vessel based on technical parameters, a propeller sizing calculator is an expert tool. Given several input data that include engine horsepower, engine RPM, gear ratio, vessel weight, hull type, and the application intended, the calculator applies performance equations to recommend a possible propeller diameter, pitch, and number of blades. These calculations are based on specific hydrodynamic theories that ensure the propeller design matches the boat's requirements for deployment, thereby further maturing in terms of efficiency. These days, calculators incorporate more sophisticated algorithms and larger datasheets, ensuring their results align with modern standards and state-of-the-art fluid dynamics. These calculators greatly help ease decision-making processes for marine engineers and operators, thereby minimizing errors and maximizing the performance of vessels.

Key Features of Propeller Sizing Calculators

Accurate Performance Prediction: Today's propeller sizing calculators will utilize the latest developments in computer models to predict the performance of various propeller configurations with high accuracy. Parameters considered might include thrust, RPM, and cavitation thresholds to maximize efficiency with minimum operational hazards.

Customizable Input Parameters: These calculators allow input for a wide range of parameters specific to particular vessels, such as hull form, displacement, engine power, and desired speed. Thus, any calculated results will address the specific performance criteria of the vessel.

Material Optimization: Today, leading calculators can help users identify a suitable material for designing a propeller, considering factors such as strength, corrosion resistance, and working environment. The aim is to provide a longer service life for the propeller while keeping maintenance costs low.

Graphical Output Facilities for Better Analysis: Most advanced calculators generate performance data of propellers using graphs. Thrust curves, power consumption graphs, and efficiency graphs—these all allow engineers to interpret data more effortlessly and make informed decisions.

Dynamic Simulation Facilities: These calculators use real-time performance simulation results to predict propeller design interactions under different operational conditions, where the load varies and water currents fluctuate. This is crucial for adjusting designs to different maritime environments.

Regulatory Compliance Integration: The propeller design is a field where maple-nugget regulations must be accounted for. Advanced calculators come with in-built frameworks to check designs for compliance with standards set by maritime authorities, thereby ensuring feasibility from both a legal and operational point of view.

Ease of Use and Accessibility: User-friendly interfaces, combined with comprehensive guidance, make the tools accessible to inexperienced users as well. Intuitive layout and step-by-step analyses help simplify the propeller sizing process while not compromising on requirements or features.

Thus, through the integration of these critical features, propeller sizing calculators serve as a crucial tool for modern marine engineering, effectively bridging the gap between theory and practice.

Advantages of Using a Propeller Calculator for Vessels

The implementation of propeller calculators gives exact and objective insights to optimize the efficiency of marine vessels. These calculators yield precise recommendations on the best propeller configuration by accepting precise inputs such as improper vessel dimensions, engine power, displacement, and operation requirements. These recommendations ensure maximum thrust output with minimum fuel consumption and cost.

Advanced propeller calculators integrate state-of-the-art algorithms to simulate hydrodynamic performances under varying conditions. This capability allows users to examine various scenarios, such as changes in load or environmental influences, thereby negating expensive trial-and-error testing. In addition to this, more detailed calculations help avoid problems with cavitation, vibrations, or mechanical failures that shorten the life of the propeller and the engine mounting system of the vessel. Hence, propeller calculators have become essential tools for marine engineers in designing vessels that are efficient and environmentally sustainable.

Steps to Calculate the Right Propeller Size

Collecting Necessary Information for the Calculation

The right propeller size can be accurately determined only when all the necessary information concerning the vessel parameters and operational characteristics is first gathered. Such key information includes the engine's horsepower (HP) and revolutions per minute (RPM), the vessel's weight and hull type, the desired cruising speed, and the reduction gear ratio. Besides these, the waterline length, beam width, and draft should also be known to ensure precision. A good knowledge of these parameters links the thrust requirements with torque and rpm, allowing for an optimized propeller design that satisfies specific requirements from the vessel. Accurate data is required to ensure that the propellers deliver on performance and do not waste energy or cause undue wear and tear on the power plant.

Using the Calculator to Determine Prop Size

The right data and correct inputs are essential when using the calculator to determine an appropriate propeller size for optimal outputs. First off, enter the vessel's specifications, considering all aspects that are influential in the calculations, such as waterline length, displacement, and hull type. Other inputs include engine performance parameters-horsepower, maximum RPM, gear ratio. The calculator takes in all the data and analyzes it using advanced algorithms and hydrodynamic theory to provide a list of recommended combinations for propeller diameters, pitches, and blade designs.

Modern propeller calculators use the latest mathematical models and industry data to provide greater precision. They consider certain environmental effects, such as water salinity, temperature, and density, because these factors affect thrust to a minor degree and thus influence the cavitation phenomenon. These advanced tools aim to reduce wasted energy and maximize thrust efficiency by designing the propeller according to the vessel's operational profile, speed requirements, and load-carrying capacity. Using this level of detail, you can confidently select a propeller that meets all performance and durability expectations.

Interpretation of the Results from the Propeller Calculator

When analyzing the outputs of the propeller calculator, it is essential to focus on the key performance indicators (KPIs) and technical parameters provided with graphical displays. Such variables include thrust outputs, fuel-performance ratios, cavitation patterns, and shaft-torque alignment. Each datum must be verified against vessel operational requirements and maritime standards to guarantee compatibility and performance optimization.

The thrust output values, for example, should align with the vessel's expected load and speed conditions while minimizing excessive drag. Further, the calculation offers insights into energy-efficiency standards by specifying the ideal diameter, number of blades, and pitch angles of the propellers that can conserve energy under varied operating conditions. The cavitation analysis could, however, give an indication of whether blade erosion or vibrations might lead to long-term maintenance assessment and operational costs.

Through the integration of such a methodical evaluation approach, a propeller calculator generates results that aid good decisions based on performance, energy conservation, and operational reliability.

Choosing the Right Prop for Your Engine

Understanding various engine types and their compatibility

In selecting a propeller, one of the critical factors to consider is the type of engine it will be attached to. To some extent, compatibility will dictate efficiency and performance. Generally speaking, engine types fall into two major categories: outboard and inboard engines. Outboard engines are perhaps lighter and more flexible, and they are typically used by smaller vessels for high-speed applications. In these applications, the propeller has to be crafted to achieve maximum thrust while avoiding cavitation at high RPMs. Inboard engines, by contrast, are found on larger vessels, where a steady output of torque and the ensuing efficiency in productivity over time take precedence. Thus, heavy-duty propellers are required to handle the continuous delivery of power.

Advances in the design of hybrid and electric propulsion systems have created new demands in propeller selection. Engines of this kind require propeller designs that maintain low noise emission and high energy efficiency, driven by increasing interest in sustainable marine operations. Determining gear ratios, shaft arrangements, and power output characteristics are parameters that help select a propeller that complements the engine's operation. Otherwise, this can lead to performance degradation, reduced mileage, or severe mechanical stress.

Integrating empirical evidence and best practices in marine engineering during the selection process can ensure that the engine-propeller package works harmoniously, thus guaranteeing performance exposure in various aquatic environments.

Choosing the Correct Propeller Size from Engine Specifications

The selection of propeller size depends on a couple of crucial parameters, each determining an engine-to-fit policy. Considerations for this include engine horsepower (HP), revolutions per minute (RPM), gear ratio, or vessel type. Propeller diameter and pitch must be selected in accordance with these parameters to allow for smooth operation and the least possible loss of energy while propelling an object.

Propellers with a large diameter and small pitch are recommended to provide increased thrust at relatively low speeds for heavy engines, especially when their vessels operate in heavier or towing conditions. Smaller diameter and higher pitch configurations are also better for lighter and faster ships, increasing speed and enhancing fuel economy. Apparently, this study has revealed that differences in pitch of about an inch can lead to variations of up to 150-200 revolutions in engine RPM, highlighting the necessity of costly measurements for precision.

Additionally, testing has demonstrated that cavitation—caused by a propeller that operates inefficiently at certain speeds—can jeopardize both performance and structural integrity. CFD modeling and advanced load simulation systems have further improved the propeller matching process, allowing operators to predict the performance of specific configurations under various conditions.

By considering these factors and employing contemporary analytical methods, operators can select the best propeller size to optimize engine performance while ensuring the durability of engine and propulsion system components.

Specific Considerations for Prop Sizing by Yamaha Engines

Usually, Yamaha engines are very precisely engineered, so one must focus on particularities beforehand when selecting a propeller. Very important considerations would be engine horsepower, maximum allowable RPM range, and gear ratio, which in turn affect the pitch, diameter, and blade design of the propeller. For instance, improper pitch can cause the engine to operate below the range of RPM it should and place more load on it, hence causing engine inefficiency.

Yamaha recommends selecting a propeller size that ensures the engine operates within its specified wide-open throttle (WOT) range, as this is of paramount importance for power output and fuel efficiency. For example, suppose a Yamaha outboard engine is designed to run at 5,000 to 6,000 RPM. When running at full throttle under normal load conditions, the selected propeller should deliver performance within that range.

In addition, material selection, which determines performance characteristics, could be essential. Aluminum propellers, lighter and less expensive, fall into the general-purpose category. Stainless steel propellers, conversely, offer greater durability and precise performance due to their thinner, stiffer blades, which tend to flex less at high speeds.

Other environmental concerns may need to be taken into account, such as the salinity of the water, elevation, and the actual use of the vessel- i.e., leisure cruising or high-speed performance. These factors may require specification alterations to the propeller to best suit the propulsion dynamics. With Yamaha's proprietary test equipment and guidelines in place, a boat owner or operator may precisely tailor propeller choices to fit their requirements, thus guaranteeing reliability, efficiency, and longevity for their engines.

The Future of Propeller Sizing and Selection

Emerging Technologies in Propeller Design

When considering emerging technologies for propeller design, it is noted that these new technologies are changing efficiency and performance criteria pertinent to the marine industries. From my research, CFD application in propeller engineering seems to be among the topmost innovations of the present day. With CFD, the manufacturer is capable of simulating water flow alongside the propeller with near-perfect precision, allowing the generation of blade designs that minimize drag and maximize thrust. Through such simulations and hydrodynamic optimizations, manufacturers can build propellers that are further optimized for fuel efficiency, creating fewer vibrations and noise throughout operation, thereby improving operational efficiency and comfort onboard.

Another major development is in the integration of propeller manufacturing with advanced materials such as carbon fiber composites and titanium alloys, which present considerable advantages in terms of weight and strength. Composite materials that are relatively light also help in lessening the existing stress on the engine, thereby improving fuel efficiency and the lifespan of propulsion systems. On the other hand, advances in AI and intelligent sensor technology are making new developments, such as shape-memory or adaptive propeller blades capable of changing pitch in real time to contest varying water conditions, more feasible.

It is noteworthy that focus is increasingly being diverted toward sustainability in propeller design. The researchers and manufacturers are investigating biodegradable materials and environmentally friendly coatings to lessen the environmental impact of marine operations. Together, these advances have ushered in a new era of propeller designs focusing on efficiency, flexibility, and sustainability to meet the demands of modern watercraft users.

The Evolution of Propeller Sizing Calculators

According to my research, it appears that propeller sizing calculators have changed dramatically throughout history, taking full advantage of advances in computational technology and accessibility to offer highly accurate outputs. Early propeller-sizing systems were mainly manual, performing calculations using empirical formulae and standardized charts. The procedure required a thorough understanding of hydrodynamics and performance parameters and was quite time-consuming and prone to human error. With the advancement of computational techniques, this transition from manual to digital calculators enhanced efficiency and precision, reducing the incidence of errors.

Modern propeller sizing calculators integrate state-of-the-art algorithms and big data to consider almost every variable, including vessel size, engine capacity, load distribution, and operational conditions such as water salinity and temperature. They are user-friendly interfaces often found online or as an app. Hence, these are accessible to users and do not require any specialized expertise. Some of the front-line calculators have 3D modeling and simulation functions to allow the user to view how differing propeller setups will influence vessel performance in a virtual environment. This has been somewhat useful for manufacturers and naval architects to finalize the designs prior to physical testing.

Future foresight has brought me to Konotop, where I realized AI and machine learning are entering into the next stage of propeller-sizing tool revolution. The dynamism brought about by these technologies allows the calculators to learn from past decisions by analyzing performance data from existing propeller installations and refining their recommendations over time. The second significant development is the presence of IoT sensors in marine systems, which means real-time data streams directly feed into these digital calculators for adequate adaptation to varying conditions. For the evolution of propeller sizing calculators, a good example is provided of the growing alliance between technology and marine engineering to ensure solutions that are not only precise but also adaptable to the current needs of marine technology.

Closing Thoughts on Choosing the Best Propeller for Your Needs

Verifying the technique of selecting a propeller for its optimal application involves using precise technical criteria with the tools available today. Among the main parameters that determine the kind of propeller are the power delivered by the engine, the type of vessel, the hull design, and the operational requirements. Pitch, diameter, and number of blades in turn affect factors like speed, fuel consumption, maneuverability, etc. Therefore, one must keep all of these in mind while considering a particular water condition in which the vessel shall operate. These include variables like water salinity, temperature, and actual load on the boat.

Modern simulation technologies, such as CFD (Computational Fluid Dynamics), are among the factors I keep in mind, as they enable detailed modeling of propeller performance before any physical production begins. This helps refine the choices by accurately simulating real-world outcomes, thereby saving both time and cost. In other words, combining this with IoT sensors that provide real-time performance data makes it possible for adaptive systems to control propeller operation dynamically, maximizing efficiency under varying environmental conditions.

Therefore, among all propositional candidates, the one that best fits the technical specifications of the vessel and the specific operational scenarios it will face is indeed the ideal propeller. By staying abreast of state-of-the-art marine engineering developments, consulting with professionals, and utilizing enabling tools, one can make considered choices that ultimately guarantee adequate reliability and better performance for the propeller over time.

Reference Sources

-

Vicprop - Free to Use Propeller Sizing Calculators: Offers tools to determine the best combinations of power, gear ratio, and propeller size for your vessel.

-

Honda Marine - Prop Calculator: Provides a calculator to guide users in selecting the proper propeller based on boat hull type and boating style.

-

SOLAS - Prop Finder: A tool to search for propeller part numbers and find the best match for your needs.

Frequently Asked Questions (FAQs)

How does a propeller size calculating tool work?

The propeller size calculator works with such parameters as the model of the boat, engine type, and the intended performance. After entering the data on the type of boat hull and the maximum RPM of the engine, it will provide you with the parameters of propeller size and pitch suited to your requirements. It examines a combination of other influencing factors to determine the right propeller for your boat, ensuring maximum thrust and efficiency. It allows you to select a propeller for your boat's acceleration needs to achieve maximum top speed.

What considerations go into selecting a propeller?

The engine horsepower, the gear ratio, and the activity of the operator determine the selection of any given propeller. The materials of construction, aluminum or stainless steel, affect performance and durability. The blade pitch and the number of blades influence thrust and acceleration. If you understand how all these elements interact, your decision-making will become more knowledgeable and bring about the desired results from the boat.

How do I go about determining the correct propeller for my boat?

The necessary data for propeller selection consists of the engine specs with max RPM and rating in HP. With a prop sizing calculator, you enter this data along with hull specifications of your boat. The calculator takes your data and gives you recommendations on pitch, diameter, and blade formation. Consider the manufacturer's guidelines and your performance objectives, such as theoretical speed requirements or fuel economy.

Does pitch really matter when it comes to performance?

The propeller pitch is a decision made with the understanding of the conditions under which the boat will perform best in mind. The greater the pitch, the greater the speed, though such an increase can demand power to reach maximum RPM. Conversely, a lesser pitch will allow for quick acceleration below rather than thrusting at higher speeds. A go-by for a smooth drive should align with the engine fitted and the purpose of the boat. Thus, with prop sizing calculators, you can analyze drastically different pitch variations to get the pitch that best suits the intended boating needs.

Do outboard motors really enable the use of a prop calculator?

Yes, it is a prop calculator that can greatly assist one in selecting the appropriate outboard motor for a particular boat. By feeding in displacement, horsepower, and gear ratio information of the outboard engine, the calculator will return the propeller diameter and pitch that produce maximum thrust and efficiency. This means an analysis whereby the outboard motor and propeller system can be evaluated side-by-side to ensure they provide the specified rates of acceleration and top speed. Choosing the right propeller ensures the best overall performance from your marine setup.

What does thrust have to do with the sizing of a prop?

Thrust is a key variable considered in propeller sizing, as it essentially defines your boat's ability to traverse through water efficiently. The selected propeller must supply enough thrust to counterbalance the weight and drag on the ship, both of which are affected by the hull's design and water conditions. You can determine the thrust performance and efficiency of various props using a propeller sizing calculator. Make sure that your propeller is producing enough thrust for smooth running and better control of your vessel.